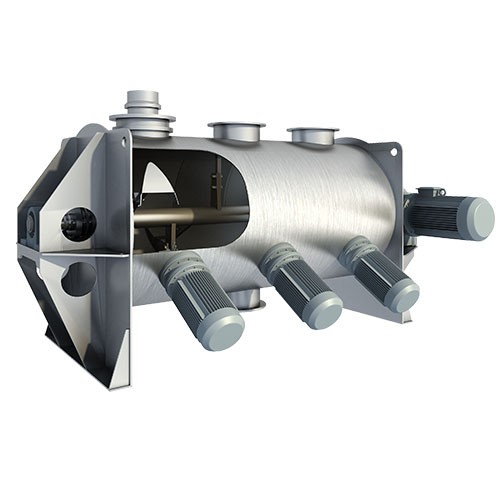

Plough Shear Mixer

Brief Introduction

Vortex Horizontal Plow Mixers create a mechanical, fluidized bed mixing action. The mixing tools project and hurl material away from the wall into free space in a crisscross direction, and inversely back again. The plow separates and lifts the product in a three-dimensional motion, while the number and arrangement of the tools insure agitation back and forth along the length of the vessel. The size, number, geometric shape, arrangement, and peripheral speed of the mixing tools are designed to achieve this mixing action for each specific application. When required, the mix action is assisted by high shear chopper devices: independent high-speed motors with customized blades for adding shear to the product mix.

Plough Shear Mixer (also named ploughshare mixer, plow mixer, plough mixer) consists of a cylindrical drum containing plough shaped mixing elements that are mounted on a horizontal shaft. It creates a mechanical fluidized bed mixing action. The mixing tools project and hurl material away from the wall into free space in a crisscross direction, and inversely back again. The plow separates and lifts the product into three-dimensional motion, while the number and arrangement of the tools insure agitation back and forth along the length of the vessel. When required, the mix action is assisted by high speed chopper devices–independent high-speed motors with customized blades for adding shear to the product mix.

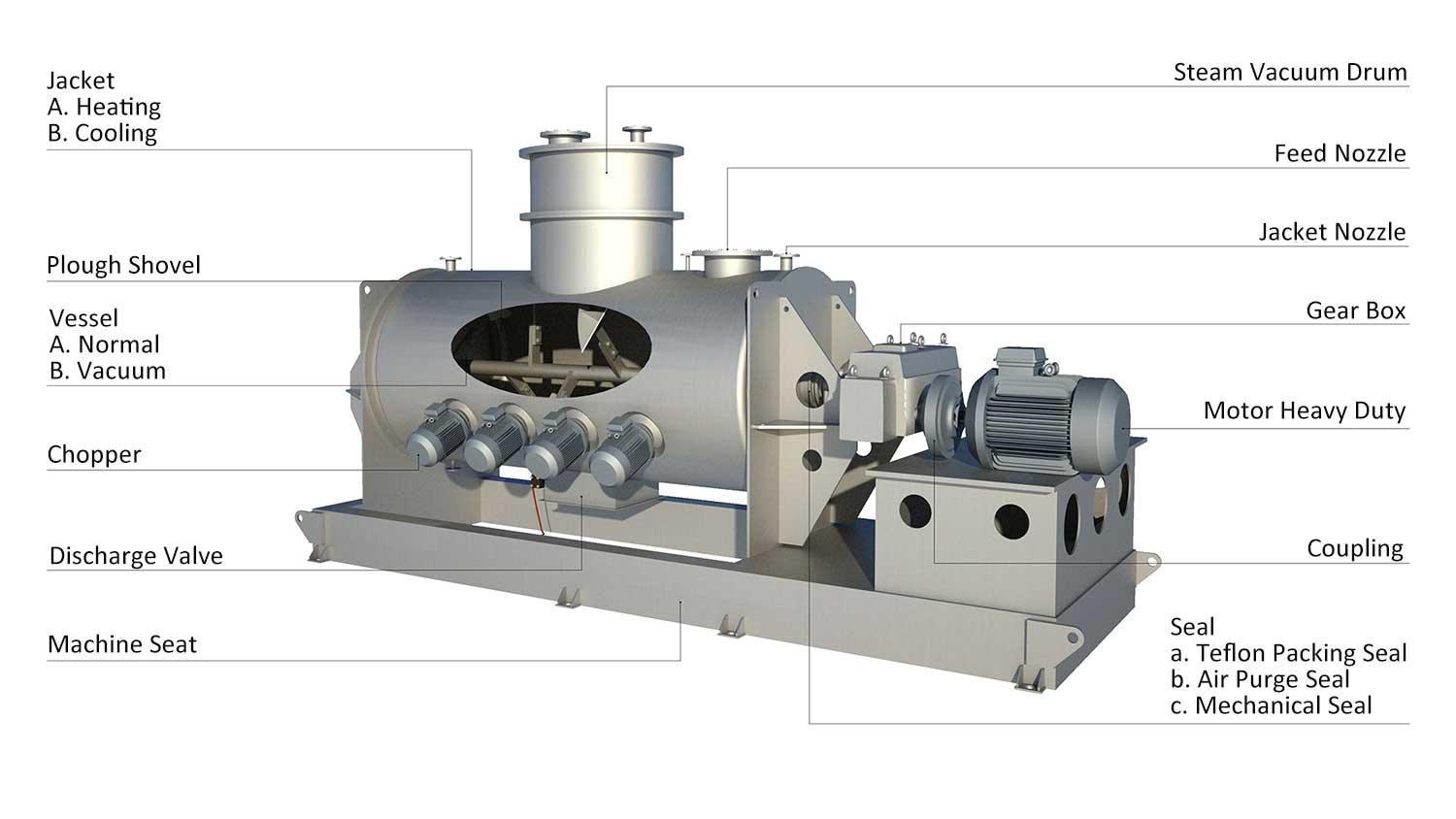

| Structure of Plough Shear Mixer | |

|---|---|

| A、Drive Unit Vortex standard ribbon blender equips gear reducer, which features high torque, low noise, perfect performance. For big ribbon blender, we add a shaft coupler to protect drive unit. |

| B、High Speed Chopper Independent high-speed motors with customized blades for adding shear to the product mix and break lumps during mixing |

| C、Liquid Sprayer Liquid could be sprayed into mixer at mixing, and high speed chopper also helps to disperse the liquid and avoid agglomerates |

| D、Heat/Cool Jacket Heat or cool jacket is optional for vortex plough mixer, the mixing materials could be heated or cooled by injet hear/cool media into the jacket. Heat media could be hot water, steam or thermal oil. Cool media could be cool water. |

| E、Discharge Valve Vortex plough mixer usually equips pneumatic flap valve, it is well sealed with the vessel and ensure no leakage. |

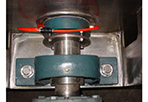

| F、Shaft Seal Vortex plough mixer use combined seal structure, the standard seal is oil seal + Telfon packing seal + Air Purge seal, the seal could prevent fine powder and micron granule entering bearing system. |

| Technical Parameters of Plough Mixer | |||||

|---|---|---|---|---|---|

| Model No. | Total Volume(M³) | Load Factor | Motor Power(KW) | Dimensions(mm) | Weight(kg) |

| PM-0.1 | 0.1 | 0.4-0.6 | 3 | 1270×865×850 | 430 |

| PM-0.3 | 0.3 | 0.4-0.6 | 4 | 2070×1050×1150 | 950 |

| PM-0.5 | 0.5 | 0.4-0.6 | 7.5 | 2180×1200×1300 | 980 |

| PM-1 | 1 | 0.4-0.6 | 11 | 2830×1620×1550 | 1800 |

| PM-2 | 2 | 0.4-0.6 | 18.5 | 3420×1810×1758 | 2520 |

| PM-3 | 3 | 0.4-0.6 | 18.5 | 3420×2045×1983 | 3200 |

| PM-4 | 4 | 0.4-0.6 | 22 | 4200×2140×2123 | 4836 |

| PM-6 | 6 | 0.4-0.6 | 30 | 4680×2290×2448 | 8775 |

| PM-8 | 8 | 0.4-0.6 | 45 | 5560×2390×2608 | 9360 |

| PM-10 | 10 | 0.4-0.6 | 55 | 5140×2390×2850 | 9750 |

| PM-12 | 12 | 0.4-0.6 | 55 | 5720×3110×2960 | 10660 |

| PM-15 | 15 | 0.4-0.6 | 75 | 5920×3280×3140 | 11050 |

| PM-20 | 20 | 0.4-0.6 | 75 | 8000*2400*3000 | 13800 |

| PM-30 | 30 | 0.4-0.6 | 120 | 10000*2600*3500 | 18500 |

| Model No. | Total Volume(M³) | Load Factor | Motor Power(KW) | Dimensions(mm) | Weight(kg) |

- stainless steel plough mixer

- small plough mixer

- plough mixer packed

- 3000L plough mixer

- jacket plough mixer

- carbon steel plough mixer

- Plough Mixer

- 500L plough mixer