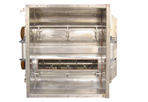

Twin Shaft Paddle Mixer

Brief Introduction

Twin shafts paddle mixer’s main task is to produce a homogeneous mixture, independent of size, shape and density, in shortest possible time. The batch mixer is considered as one of the best in homogeneity and it has been used for decades within all processing industries.Twin shafts paddle mixer’s main task is to produce a homogeneous mixture, independent of size, shape and density, in shortest possible time. The batch mixer is considered as one of the best in homogeneity and it has been used for decades within all processing industries.

The two axes of mixing interior rotates to different sides and paddles attached to the axes forms fluidized area by diffusing mixed materials to different directions according to stable apex speed. At this time, the movement of materials is concentrated on the higher center part from the bottom of mixer, and therefore, the effective volume of mixing room increases, and as the effective volume increases, the collision and rubbing between materials decrease.

| Structure of Twin Shaft Paddle Mixer | |

|---|---|

| A、Mixing Homogeneity Vortex twin shaft paddle mixer perform well when mixing materials with varied bulk density, particle size and ratio. Its CV value is less then 3%. |

| B、Crush Device Vortex broken-device on the twin shaft paddle mixer could break agglomerates. Its rotation speed is over 1000rpm. |

| C、Discharge Device Vortex standard twin shat paddle mixer equips pneumatic discharge valve, there is small opening and big opening design for paddle mixer. Big opening ensure thoroughly discharge. |

| D、Two-chip Paddle Leaf Vortex standard twin shaft paddel mixer's paddle leaf consis of two pieces, it is changeable when worn down. |

| E、Drive Unit Vortex standard twin shaft paddle mixer equips gear reducer, which features high torque, low noise, perfect performance. For big ribbon blender, we add a shaft coupler to protect drive unit. |

| F、Shaft Seal Vortex standard twin shaft paddle mixer could be up to 20 cubie meter. |

| Technical Parameters of Twin shaft Paddle Mixer | |||||

|---|---|---|---|---|---|

| Model No. | Total Volume(M³) | Load Factor | Motor Power(KW) | Dimensions(mm) | Weight(kg) |

| TPM-0.05 | 0.05 | 0.4-0.6 | 1.5 | 1290×660×837 | 230 |

| TPM-0.2 | 0.2 | 0.4-0.6 | 4 | 1124×1110×720 | 260 |

| TPM-0.4 | 0.4 | 0.4-0.6 | 4 | 1400×1250×1030 | 450 |

| TPM-0.5 | 0.5 | 0.4-0.6 | 7.5 | 1450×1500×950 | 800 |

| TPM-1 | 1 | 0.4-0.6 | 11 | 1800×1800×1350 | 1150 |

| TPM-1.5 | 1.5 | 0.4-0.6 | 15 | 1850×1950×1180 | 2100 |

| TPM-2 | 2 | 0.4-0.6 | 18.5 | 2200×2400×1600 | 2800 |

| TPM-2.5 | 2.5 | 0.4-0.6 | 22 | 2300×2300×1620 | 4200 |

| TPM-4 | 4 | 0.4-0.6 | 22 | 2680×2400×1850 | 4500 |

| TPM-5 | 5 | 0.4-0.6 | 37 | 2950×3050×2040 | 6000 |

| TPM-6 | 6 | 0.4-0.6 | 45 | 3050×3250×2100 | 7000 |

| TPM-10 | 10 | 0.4-0.6 | 55 | 3550×3150×2400 | 8000 |

| TPM-12 | 12 | 0.4-0.6 | 55 | 4695×3180×2500 | 10500 |

| TPM-15 | 15 | 0.4-0.6 | 55 | 4180×3960×2600 | 10000 |

| TPM-20 | 20 | 0.4-0.6 | 75 | 5700×3700×2500 | 13000 |

| Model No. | Total Volume(M³) | Load Factor | Motor Power(KW) | Dimensions(mm) | Weight(kg) |