Ribbon Blender Mixer

Brief Introduction

The ribbon blender’s versatility for blending solids combined with it’s ability to perform heating, cooling, coating, and other processes make it a very popular mixer.Vortex corporation has been a ribbon blender manufactuer since 1989, decades years’ experience and constant improving technology makes vortex ribbon blender stand out

WhatsApp: +86 18039118812

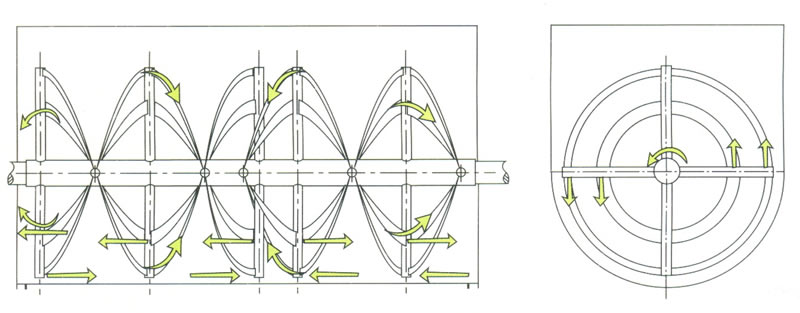

Ribbon Blender (also named ribbon mixer) is a basic industrial mixing machine. They consist, basically, of a trough-shaped shell (usually 2 to 3 times longer than it is wide) with a semicircular bottom, fitted with a horizontal longitudinal shaft on which are mounted arms supporting a combination of ribbon blades, paddles or helical screws set at a fairly close clearance to the semicircular mixer body so that no layer of material remains on the bottom of the ribbon mixer. The most effective design of ribbon layout is the double spiral in which the outer ribbon moves the product in one direction and the inner ribbon moves it in the opposite direction.

The ribbons rotate and move materials both radially and laterally to insure thorough blends in short cycle times. Ribbon agitators are used for blends that will be between 40 and 70% of the rated capacity of ribbon blender.

| Structure of Horizontal Ribbon Blender Mixer | |

|---|---|

| A、Drive Unit Vortex standard ribbon blender equips gear reducer, which features high torque, low noise, perfect performance. For big ribbon blender, we add a shaft coupler to protect drive unit. |

| B、Flexible Disassembly Vortex ribbon blender use flange connection between main shaft and drive shaft, and thus it is easy to disassembly when maintenance. |

| C、Top Cover The top cover of vortex ribbon blender could be fully opened, half opened, and fully closed. And its inlet size could be custom made upon customer's requirement. |

| D、Discharge Valve Vortex ribbon blender usually equips pneumatic flap valve, it is well sealed with the vessel and ensure no leakage. |

| E、Heat/Cool Jacket Heat or cool jacket is optional for vortex ribbon blender, the mixing materials could be heated or cooled by injet hear/cool media into the jacket. Heat media could be hot water, steam or thermal oil. Cool media could be cool water. |

| F、Shaft Seal Vortex ribbon blender use combined seal structure, the standard seal is oil seal + Telfon packing seal + Air Purge seal, the seal could prevent fine powder and micron granule entering bearing system. |

The size of Vortex ribbon blender vary from 100L to 30000L. and the out-form dimensions could be custom made as per customer’s requirement.

| Technical Parameters of Ribbon Blender | |||||

|---|---|---|---|---|---|

| Model | Total Volume(M³) | Load Factor | Motor Power(KW) | Dimensions(mm) | Weight(kg) |

| VRB-0.1 | 0.1 | 0.4-0.6 | 3 | 1190×740×770 | 330 |

| VRB-0.3 | 0.3 | 0.4-0.6 | 4 | 2030×630×980 | 720 |

| VRB-0.5 | 0.5 | 0.4-0.6 | 7.5 | 2320×730×1130 | 980 |

| VRB-1 | 1 | 0.4-0.6 | 11 | 2800×920×1320 | 1700 |

| VRB-1.5 | 1.5 | 0.4-0.6 | 11 | 3180×1020×1550 | 1800 |

| VRB-2 | 2 | 0.4-0.6 | 15 | 3310×1120×1640 | 2100 |

| VRB-3 | 3 | 0.4-0.6 | 18.5 | 3750×1290×1820 | 3000 |

| VRB-4 | 4 | 0.4-0.6 | 22 | 4220×1400×1990 | 3980 |

| VRB-5 | 5 | 0.4-0.6 | 22 | 4220×1500×2100 | 4620 |

| VRB-6 | 6 | 0.4-0.6 | 30 | 4700×1610×2260 | 6180 |

| VRB-8 | 8 | 0.4-0.6 | 37 | 4420×2150×2470 | 8200 |

| VRB-10 | 10 | 0.4-0.6 | 45 | 5520×2960×2720 | 8920 |

| VRB-12 | 12 | 0.4-0.6 | 45 | 5720×3010×2840 | 9520 |

| VRB-15 | 15 | 0.4-0.6 | 55 | 5840×3540×2940 | 9950 |

| Model | Total Volume(M³) | Load Factor | Motor Power(KW) | Dimensions(mm) | Weight(kg) |

- 2000L ribbon blender

- heavy duty ribbon blender

- ribbon

- ribbon blender with cylinder vessel

- safety grid of ribbon blender mixer

- sanitary ribbon blender

- stainless steel ribbon blender mixer